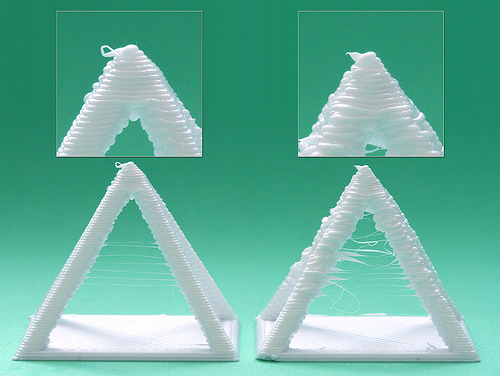

Whether you're using a dedicated support material like PVA or HIPS or you're using a single extruder printer and using the same material as your support material, it's important to have your support settings calibrated. You might even consider a new ducting for the cooling fan to try and direct the airflow toward the part.ĭrooping, curling, and hanging filament all lower the score, especially when the lower angles have difficulty.

It is important to consider that the type of fan used for layer cooling (axial vs radial) and the direction your fan outlet is facing will impact how well an overhang is printed, so it would be wise to print this test rotated every 90 degrees to see if some faces fair better than others. Printing speed does affect cooling, so the lower the print speed, the more time for freshly laid down filament to cool before the next layer is ready.Ī small print with high print speeds is going to need much more cooling than a large print at slow speeds since material will have only a very brief amount of time to cool enough to solidify. This test is designed to see how well the printer can cool down the hot plastic as it is extruded the better the cooling, the cleaner the bottom surface is.

0 kommentar(er)

0 kommentar(er)